Role of Electric Vehicles in the Mining Industry: A Sustainable Transformation Approach

With increased pressure from consumers and investors, most mining companies have started adopting sustainable mining practices. Owing to the increase in digitalization, replacement of aged assets to increase operational efficiency, concurrently improving workers’ health and safety, and, reducing emissions, adoption of EV is the talk of the day. Citing key challenges and opportunities, this blog summarizes how Battery Electric Vehicle (BEV or EV) adoption will benefit the mining industry. Further, it explores more on the ongoing sustainable evolution of ‘Mine Electrification with a focus on EV adoption’ across the mining value chain.

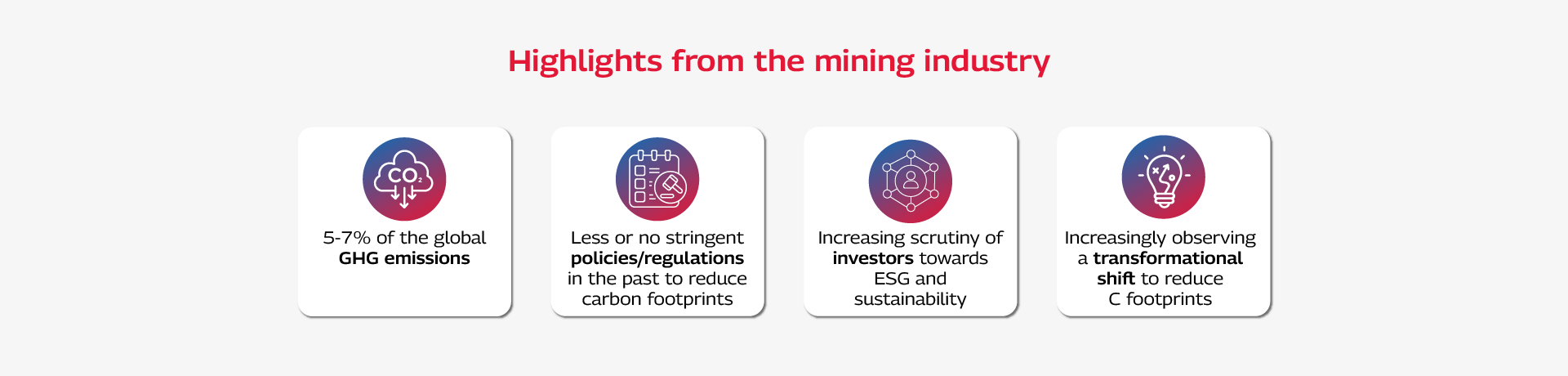

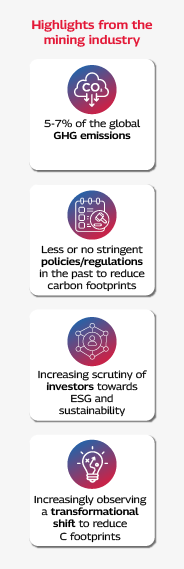

Current Trends in the Mining Industry

With sustainability in focus, the world is now aligning itself towards cleaner energy technologies. To address this growing pressure of adopting clean energy technologies, the demand for specific minerals is going to rise manifold in the next 20-30 years. Target mining of these high-grade mineral ores has significantly depleted their concentrations in the Earth's crust, and this decline continues. In the future, extracting these minerals will demand larger operational footprints, leading to higher energy and freshwater consumption. Today, the production of these minerals through toxic practices will not address the purpose of sustainability. As a result, many countries are implementing new regulations, offering subsidies, and imposing penalties to promote sustainable mining practices.

With more stringent laws and regulations defining green metals across the mining supply chain, the mining industry is realigning itself for a sustainable future. The adoption of BEVs with mine electrification complemented by renewable energy sources and digitalization, is crucial to be a responsible and sustainable mining player.

The adoption of electric vehicles (EVs) in mines represents a significant change during this transformation phase. EV adoption comes with certain challenges, such as being capital-intensive, big infrastructure requirements, and technological improvements along with interesting benefits such as reduced noise, heat, vibration, emission, and TCO with enhanced efficiency and productivity. Currently, there are no regulations mandating mine electrification. Hence, rolling out EVs in a mine requires commitment towards a sustainable future.

Rolling out EVs in Mining

The total GHG emission contributions of the mining industry range between 1.9 to 5.1 gigatons of CO2 equivalent to GHG emissions (McKinsey & Company, 2020)1. While this accounts for a modest portion, there is significant potential to lower this further. By adopting a proactive and sustainable approach like usage of EVs in mining operations, companies can not only reduce their GHG emissions, but also comply with industry regulations and global standards.

In 2021, an international council representing over 25 key mining players and more than 30 commodities associations worldwide, had committed to a net-zero goal for scope 1 and 2 greenhouse gas (GHG) emissions by 2050 or sooner.

This push for sustainability is complemented by advanced mining practices like electrification, replacement of diesel-powered heavy earth moving machines (HEMMs), and haul trucks with BEVs and automation to improve the health and safety of workers.

The replacement of aging assets with BEVs and electrification of a mine requires substantial capex investment along with infrastructure to sustain the electric vehicles. Major mining players are committing to sustainable development through technological advancements and partnering with EV players for new technology developments. Leading mining companies have collaborated with leading manufacturers of equipment for mining to test battery-electric haul trucks with target commercialization before 2030. Additionally, mining players are investing seriously in EV technology development and adoption. To enable this EV deployment a success, mine electrification is going to be the very first step.

Due to the increased demand for minerals and metals for clean energy, mining operations are increasingly focused on efficiency and sustainable practices. Going forward, mine electrification will be a principal component in this decarbonization era. This mine’s electrification is not only limited to the use of renewable energy sources but also extended to the integration of EVs. The complete electrification of mining operations, including the charging of BEVs through renewable energy, is essential. Through this complete electrification and renewable energy sources, the mining industry will be able to address scope 1 and 2 emissions together.

Henrio, Motta, Ray, and Ende (2023) from McKinsey & Company mention in their Materials Practice publication that “a fully electrified mine with renewable-power sources could have a carbon footprint that is 60 to 80 percent lower, avoiding carbon taxes and capturing potential green-product premiums.”2

Hence, the EV adoption trend is going to be the game changer for the mining industry in achieving net zero goals faster.

EV Adoption

In any mine, most of the emissions (carbon, noise, and heat) are caused by diesel-powered vehicles and machinery with haul trucks being the top emitter amongst all. During mine electrification, EV adoption will play a commanding role in new mines from the development stage itself and in operating mines through the replacement of aged assets (haul trucks, HEMMs, etc.) with advanced and automated electric vehicles.

Though the EV adoption in mines is at an early stage, more and more OEMs are investing heavily in R&D for the electrification of their products. Mining companies, which are generally low greenhouse gas emitters and face few sustainability regulations, have not received significant incentives for electrification. However, a single automated electric haul truck in an opencast mine can save a couple of million dollars as compared to a diesel-operated haul truck during its lifetime. Hence, the main push will be seen due to low TCO, increased safety, and productivity. To control cost, rather than replacing the complete fleet with EVs, many mining players are retrofitting their existing diesel-operated fleets to electric vehicles. The EV market for the mining industry is expected to grow to over $30 billion by 2050.

Conclusion

Driverless BEVs are going to transform the mining industry globally. However, this transformation comes with its own challenges and opportunities. The following statements conclude this blog with a mention of certain challenges (risks) and opportunities (with benefits) of EV adoption with mine electrification:

- The mine electrification asks for a large capital investment and infrastructure upgrade.

- Heavy-duty driverless BEVs require advanced technology development to make them market competitive.

- Low-cost EVs with safe, faster charging and high-power density batteries will be required to replace the mining fleets. The fire, heat, and shock risks shall be kept in mind while designing these advanced BEVs.

- Battery disposal of BEVs is another hazardous task that needs to be addressed before we proceed with large-scale BEV implementation.

- A separate skilled workforce needs to be trained while adopting driverless BEVs along with mine electrification.

- The mine design also needs realignment while adopting new technologies during electrification.

- Electrifying a mine will increase its electricity demand by manifolds. Hence, the source of electricity must be renewable energy keeping sustainability in mind.

- Collaboration between mining companies, OEMs, and other relevant technology players to implement electrification across the mine will play a crucial role in EV adoption.

- Governments can also play a major role in EV adoption for the mining industry through subsidies tax credits or new regulations encouraging EV adoption.

In conclusion, EV adoption will not only reduce operational expenses (OpEx) due to lower electricity costs as compared to diesel costs and reduced maintenance but will also increase operation efficiency and productivity. Additionally, EVs will improve miners’ health and safety due to low CO2 emissions and decreased noise and vibrations enabling mining players to succeed in their commitment to sustainability.

Krishna is a qualified Mineral Engineer from IIT(ISM) Dhanbad having over 17+ years of experience across distinct though connected verticals, domains, and competencies. From processing plant D&E to processing technology development and sales to state governments’ mineral policy advocacy to participating in the mineral auctions are a few of his working subjects in the past.

MoreKrishna is a qualified Mineral Engineer from IIT(ISM) Dhanbad having over 17+ years of experience across distinct though connected verticals, domains, and competencies. From processing plant D&E to processing technology development and sales to state governments’ mineral policy advocacy to participating in the mineral auctions are a few of his working subjects in the past.

At Tech Mahindra, Krishna is working as a Metals and Mining SME. With his deep domain knowledge, he is responsible for architecting new solutions across the mining value chain.

Less