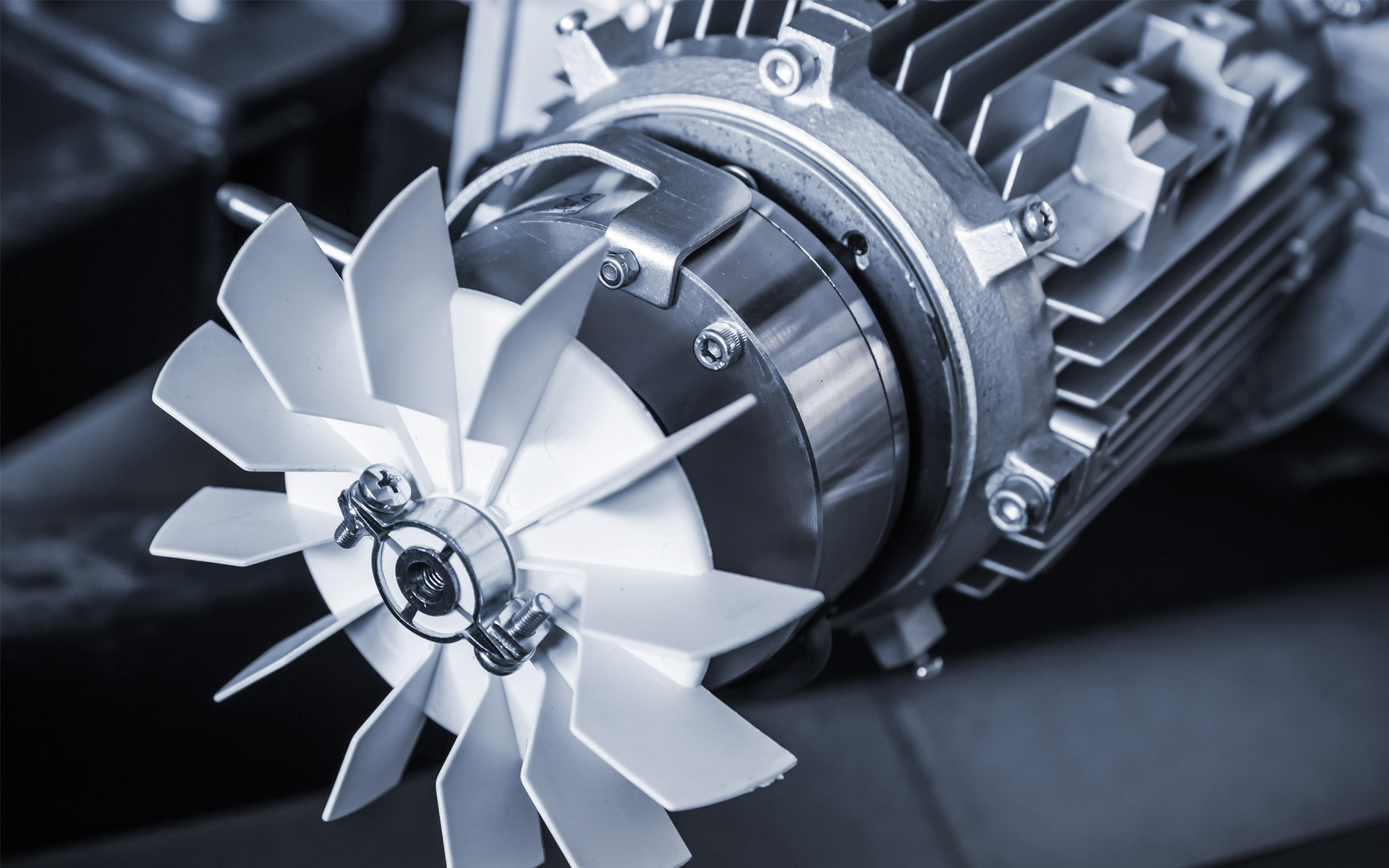

Predictive Maintenance for a Leading Electric Motors Company

Business Overview

Japanese manufacturer of electric motors whose products are found in electric appliances, hard-disk drives, automobiles, and commercial and manufacturing equipment.

Challenge

The goal of conducting an Industry 4.0 assessment is to address two specific areas: the cost of maintenance and the local team's turnaround time for troubleshooting, as well as the availability gaps for customers caused by slow communication and action between different geographies.

Approach & Solution

Tech Mahindra helped the customer using predictive maintenance, this included:

Key Outcomes

Browser Based Data Access

Data can be accessed anytime from anywhere using a browser on a web-enabled device

Remote Equipment Optimization

Increased equipment efficiency by remote monitoring and management

Seamless Remote Troubleshooting

Reduced business disruption due to remote troubleshooting