Remanufacturing Business Challenges and Need for Digital Interventions

The global Automotive Remanufacturing market is expected to grow from USD 65.49 billion in 2023 to USD 126.42 billion by 2030 The global Automotive Parts Remanufacturing market size is expected to reach USD 65.49 billion by 2034 end. This expansion reflects the growing significance of remanufacturing as a strategic lever in the automotive industry. Remanufacturing helps companies mitigate supply chain disruptions, reduce production costs compared to new parts, and achieve environmental goals by reducing waste and contributing to a circular economy. For many manufacturing executives, sustainability has become a top agenda, with the circular economy offering one of the highest and the most measurable ways of achieving environmental goals. Remanufacturing, as a core pillar of the circular economy, enables companies to reduce waste, conserve resources, and build long-term value through a more efficient use of materials.

Remanufacturing involves "rebuilding a product to the specifications of the original manufactured item by using a mix of reused, repaired, and new components." This process includes repairing or replacing worn-out or outdated parts, and when necessary, incorporating new elements to ensure the product achieves performance and lifespan equal to or better than the original.

This blog talks about the key challenges facing the remanufacturing business and the need for digital interventions to sustainably scale the industry.

Reviving Value: The Critical Role of Remanufacturing

In an era where sustainability is the need of the hour, remanufacturing comes in as a transformative force in the supply chain industry. A few reasons why it is crucial for the long run is:

- When auto companies encounter supply chain disruptions, increased material costs, and product shortages, they are increasingly turning to remanufacturing as an alternative solution.

- Raw material's limited availability in certain areas is leading aftermarket businesses to embrace remanufacturing to boost the need for replacement auto parts.

- Customers seek solutions that are likely to optimize quality while balancing cost and availability.

- The government is focusing on decreasing emissions leading manufacturers to prioritize remanufacturing techniques.

Components that can be Remanufactured

Remanufactured methods fulfill a similar requirement for the original equipment. Components that can be reconstructed include:

- Engine and related parts

- Transmission and related parts like brakes, wheels, AC compressors, steering, fuel system, and many more

The Electric vehicle (EV) parts that can be remanufactured include:

- Electric Motors

- Electronic components (Thermal control modules, Onboard charges, etc.)

- Charger Remanufacturing

Emerging Trends in Remanufacturing: A Sustainable Future

Leading automotive OEMs and tier 1 companies are investing in remanufacturing solutions due to their potential for sustainability and cost-effectiveness. The automotive companies are expanding their remanufacturing operations through various strategies; they invest in advanced technologies like AR/VR and automation, and they partner and collaborate with technology players to expand their remanufacturing capabilities.

The automotive companies are also expanding the remanufacturing facilities in different regions which will reduce the transportation cost and are also making sustainability initiatives.

Each company is managing the remanufacturing process to enhance product lifecycle management, reduce cost, and support sustainability initiatives.

- Sustainability through Circular Economy Focus: Companies are increasingly adopting remanufacturing to reduce waste, conserve resources, and lower their carbon footprint as part of broader sustainability initiatives. Remanufacturing aligns with the circular economy model, which emphasizes keeping products in use for as long as possible and reducing the need for new raw materials.

- Technological Advancement: Innovations in materials, processes, and automation are improving the efficiency and quality of remanufactured products, making them more competitive with new products.

- Cost Benefits: Remanufacturing offers improved reliability at a lesser cost.

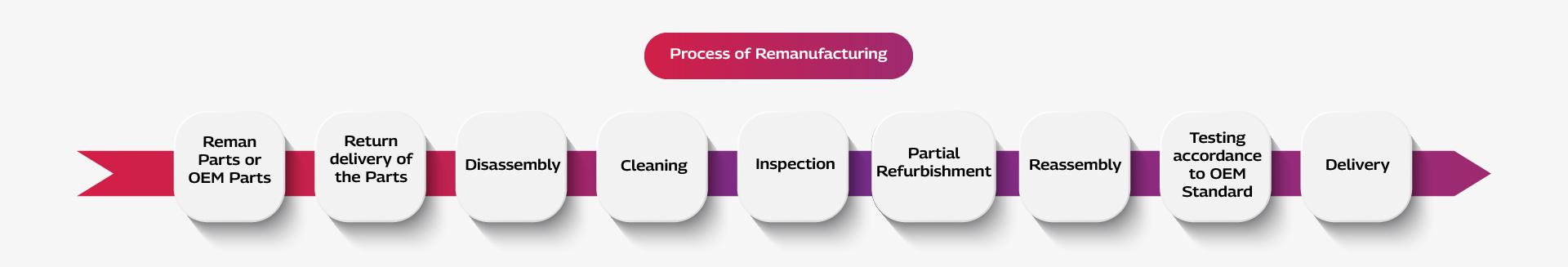

Process of Remanufacturing:

A part is returned to the remanufacturing facility, it is disassembled into the smallest part losing its original identity. Post that, each part goes into a cleaning process and is inspected by the workshop supervisor. The part that can be effectively salvaged and the accepted part is converted into productions. Again, the supervisor inspects the product, reassembles it, and delivers the product to the customer.

How can Digital Interventions Address the Remanufacturing Challenges?

Remanufacturing Industrial Challenges | Digital Interventions |

Workforce Training | Virtual training and Augmented Reality (AR): Providing virtual training programs and AR tools to upskill employees and enhance their ability to handle complex remanufacturing tasks. |

Quality control | AI Inspection Systems: Implement AI-based inspection systems for defect detection. Machine Vision Systems can be used to inspect parts for defects. |

Complex Assembly and precision fit | Automated 3D Vision Systems: Capture detailed measurements of remanufactured parts and compare them with CAD. It will provide real-time feedback on fit and alignment, ensuring precise assembly and reducing errors. |

Inventory Management | IoT-Each company is managing the remanufacturing Enabled Trackers: IoT and Data analytics can be used for real-time inventory tracking. |

Part Identification | RFID/QR Tracking: Employ RFID or QR codes with digital databases for enhanced tracking accuracy. |

Customization & Flexibility | Digital Twins: Use digital twins to model and simulate custom remanufacturing scenarios |

Component wear variability | Predictive Maintenance with ML: Machine learning algorithms analyze data from sensors installed on components to predict wear patterns and potential failures. The system uses historical data and real-time sensor readings to forecast maintenance needs. |

In summary, remanufacturing represents a powerful strategy for both cost savings and sustainability. Digital interventions are reshaping the landscape of remanufacturing, driving greater efficiency, precision, and sustainability across industries. An increase in AI, digital twins, data analytics, and IoT to enhance their remanufacturing processes will not only improve product quality and operational efficiency but also contribute significantly to environmental sustainability by extending product lifecycles and reducing waste. As industries continue to prioritize sustainability and resource efficiency, the integration of digital solutions will be crucial for advancing remanufacturing practices and achieving circular economy objectives. Embracing these technologies will help industries stay competitive, meet regulatory demands, and lead the way toward a more sustainable future.

Resources:

1.Fortune Business Insights. (n.d.). Automotive remanufacturing market size, share & industry analysis, by product type (engine, transmission, axle, others), by vehicle type (passenger vehicle, commercial vehicle), by application (OEM, aftermarket), and regional forecast, 2021-2028. Retrieved September 30, 2024, from https://www.fortunebusinessinsights.com/automotive-remanufacturing-market-107428

2.Fact. MR. (2023). Automotive parts remanufacturing market: Global industry analysis, size, share, growth, trends, and forecast 2023-2034. Retrieved September 30, 2024, from https://www.factmr.com/report/automotive-parts-remanufacturing-market#:~:text=The%20global%20automotive%20parts%20remanufacturing,171.27%20billion%20by%202034%2Dend

Keerthana B has over 7 years of experience in Automotive and IT Industry. She holds a bachelor’s degree in engineering from Magna College of Engineering and has completed Post Graduate Program in Marketing from Loyola Institute of Technology Pondicherry University, Chennai